technology

Why Use Crossflow?

Crossflow filtration offers the winemaker peace of mind when it comes to removal of bacteria from wine. When used ahead of sterile cartridges on a bottling line, the wine is bottled bacteria free and with little or no stripping effect.

The Technology – Spiral Wound Membranes

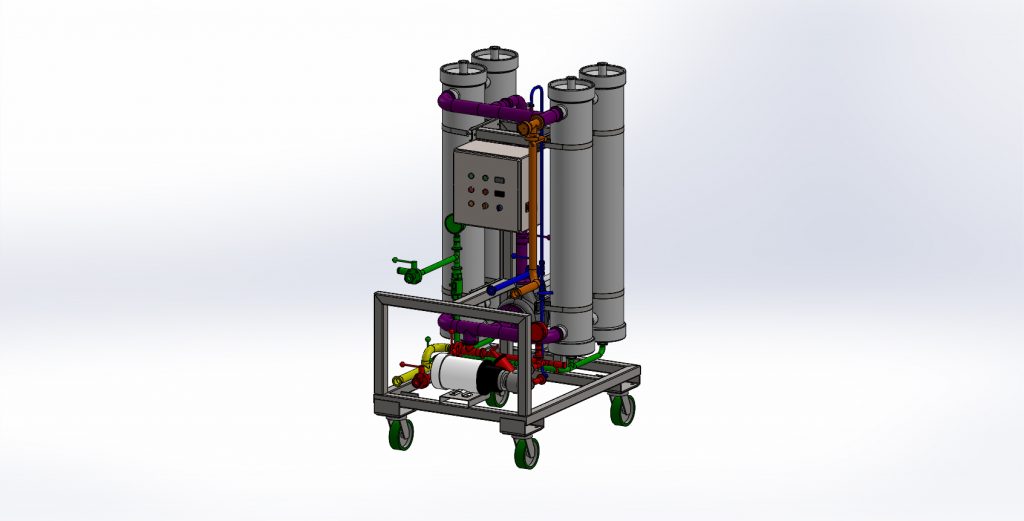

VA Filtration has mastered the art of crossflow using spiral wound membrane elements. With more than 10 years of in field experience, we have gained valuable in-field experience that has been applied to our systems. We constantly learn and adjust while always looking for a more efficient membranes to filter wine. Our spiral wound membrane filtration offers the lowest cost per square foot when compared to competitor systems. With its high surface area and low crossflow rate, we offer the winemaker an extremely gentle option for wine filtration. All systems are designed around handling the wine in a manner that protects integrity and quality. We NEVER try and filter as fast as possible. Spiral wound technology allows wine to be filtered with very low trans membrane pressures equating to gentle filtration. With the lowest replacement membrane cost in the industry, why use anything else?