technology

The Technology

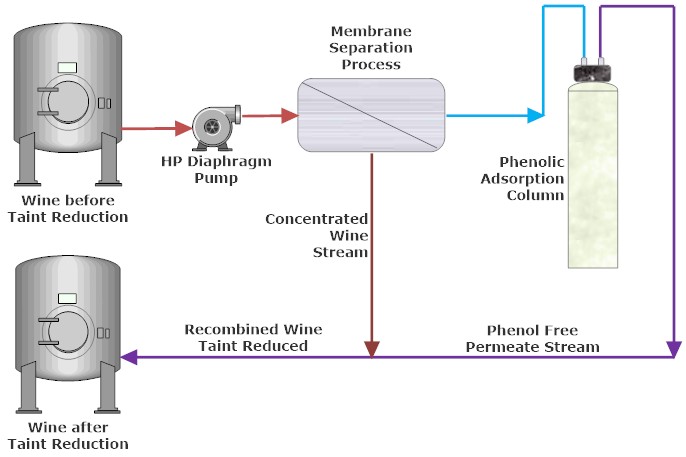

VA Filtrations Brett character reduction process is designed to be as gentle as possible on wine. Using our patented NF/Adsorption* process, we are easily able to reduce levels of 4EP to less than detectable limits without impacting wine quality. To date we have processed hundreds of thousands of gallons successfully and with minimal impact.

Advantages of our 4EP Service

- Up to 30% 4EP and 20% 4EG reduction per pass through our machinery

- Minimal impact to the quality of the wine

- Up to 1500 GPH wine flow

- No internal recirculation

- Minimal heat increase (less than 1°F)

- On-site continuous supervision